Price: Negotiable

Model Number: DF-450/600/800

Power: 15/18.5/22KW

Application: Machinery & Hardware, Construction, Stone

Weight: 8000/8500/8800 KG

Place of Origin: CHINA.

Brand Name: DAFON

Certification: CE, ISO

Minimum Order Quantity: 1 SET

Trading Method: FOB/CIF/EXW Xiamen Port

Delivery Time:90 Days

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Quality and Reliability: You'll always need a piece of equipment that's built to last, Check the supplier for high-quality and durable machines. what's materials made for the stone cutter

Design and Technology: You need to pay attention to whether the supplier uses the latest cutting technology. Is there an independent technical team? Able to accept customized production, whether to obtain technology patents

Service and Support: See if the supplier provides good customer service, including pre-sales consultation, after-sales service, repair, spare parts provision, etc. Ability to take on after-sales capacity when the machine doesn't work

Training: The ideal supplier should be able to provide operation and maintenance training to ensure you get the most out of your machine.

Price: Although purchasing a high-quality stone cutting machine may require a substantial investment, it should be considered a long-term investment to increase your productivity and the quality of your production.

Reputation: Conduct research on candidate suppliers' online reviews, word of mouth, and industry reputation.

Safety: The safety features required by the stone cutting machine should also be considered, this includes the operating safety of the machine and the safety protection facilities provided for the workers.

The above factors will help you choose the best stone cutting machine supplier for your needs.

Stone cutting machine, also known as Bridge Cutter Machine (Bridge Cutter Machine), is a machine commonly used in stone processing. Here are the basic steps for it to work:

Setting parameters: First, you need to set cutting parameters, including cutting depth, width and shape. These parameters are usually set by a computerized control system.

Placing Stone: Place stone (like granite, marble, or limestone, etc.) on the work platform. It should be ensured that the stone is placed smoothly and fixed in place.

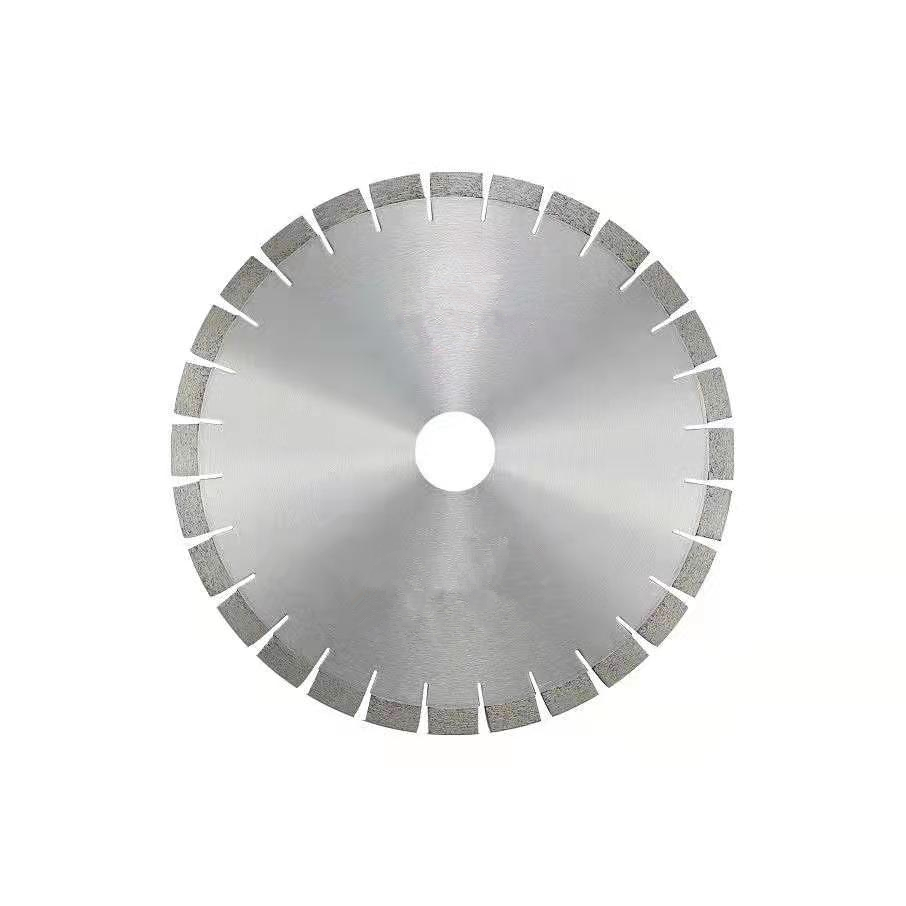

Cutting process: After setting the parameters, the blade of the cutting machine will rotate at a high speed driven by the motor to form a strong enough cutting force. Then, the blade starts cutting the stone according to the set path.

Water cooling: During the cutting process, there is usually a water source to cool the blade to prevent overheating due to friction from damaging the blade or affecting the cutting quality.

Complete cutting: When the cutting is completed, the cutting machine will stop automatically, and then the cut stone can be removed. Then clean the machine for the next use.

The bridge cutting machine improves cutting efficiency and accuracy by reducing manual operations, and is an important tool in the stone processing industry.

|

Appellation |

DF-450 |

DF-600 |

DF-800 |

Unit |

|

Blade diameter |

Ø300~450 |

Ø350~600 |

Ø400~800 |

mm |

|

Max.vertical stroke |

230 |

350 |

350 |

mm |

|

Worktable tiling degree |

0~85 |

0~85 |

0~85 |

N° |

|

Worktable rotating degrees |

0~90/0~360 |

0~90/0~360 |

0~90/0~360 |

N° |

|

Max.cutting depth |

110 |

180 |

280 |

mm |

|

Water consumption |

1.8 |

1.8 |

1.8 |

m³/h |

|

Main motor |

15 |

18.5 |

22 |

kw |

|

Total motor |

24.5 |

26 |

26 |

kw |

|

Overall dimension (L*W*H) |

6000*4800*2900 |

6000*4800*3000 |

6000*4800*3000 |

mm |

|

Gross weight |

6560 |

7580 |

8250 |

kg |

|

Worktable dimension |

3200*2000 |

3200*2000 |

3200*2000 |

mm |

Give the space a stronger sense of wholeness and high-class atmosphere...

Stone decoration is beautiful and durable, enhancing the overall texture and practicality of the space...

Create an elegant, textured, and moisture-proof bathing space to enhance the use experience....

The machine is controlled by a microcomputer, The matching table can be rotated 360° in the horizonta plane, 45° a positioning(jumpable angle positioning), 85°flap. Precision ma...

Bridge saw machineMain features The bridge saw machineadopt cast iron on the main part of machine body ensure stability while cutting. The cutting speedis controlledby inverter t...

Introduction: A tile cutting machine is a common construction tool, mainly used for cutting tiles, marble, granite, and other hard materials. It adopts advanced electric power tec...