Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-03-30

What’s Tactile Paving Slabs ?

Tactile Paving Slabs, special bricks laid on sidewalks, are an indispensable part of the city's roadways. They act as silent guides for the visually impaired and the mobility impaired.

The Tactile Paving Slabs, as their name suggests, guide the blind along the established route, avoiding roadblocks. Subtle variations in the surface texture provide them with directional information.

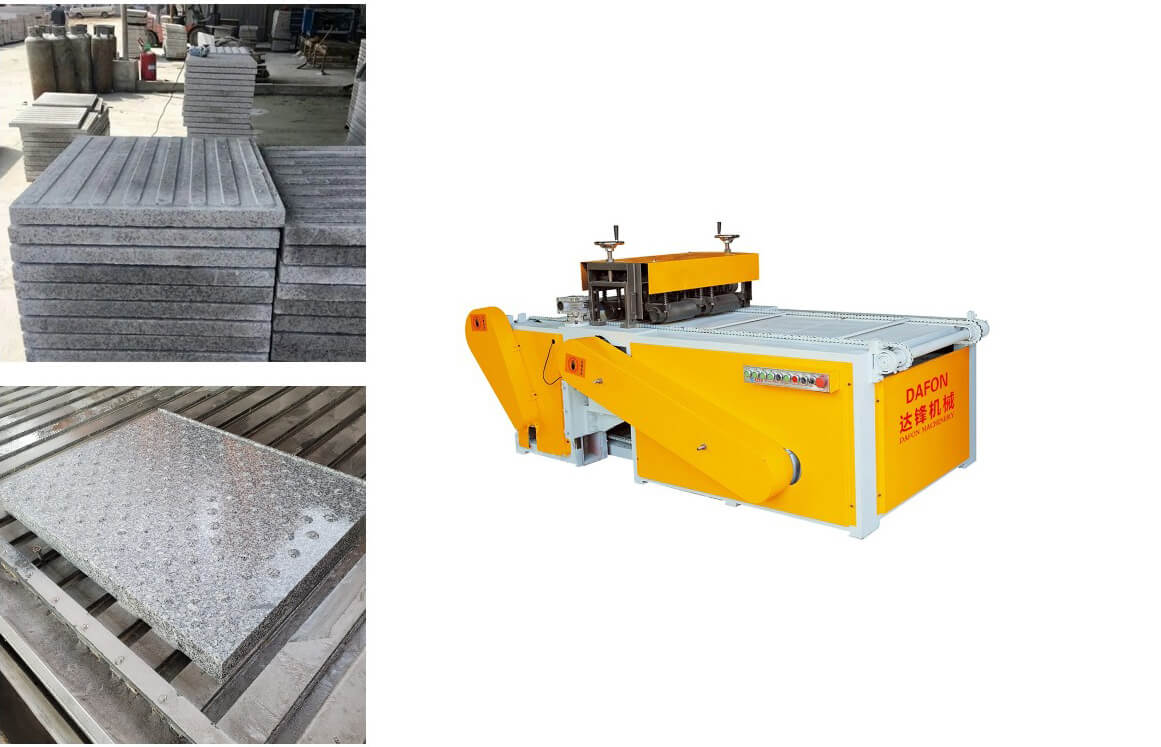

Tactile Paving Slabs with dots are "warning lights" on the road. The raised dots remind the blind of the changing road conditions ahead and the need for caution. They can be found at turns, intersections, and steps.

Which Style of Stone is Suitable for Making Tactile Slabs?

Tactile slabs, as a special presence on city roads, not only carry care and tolerance but also reflect the craftsmanship of excellence. The choice of material is especially critical.

Granite stone is the best choice for tactile slabs. Its high hardness and abrasion resistance ensure the durability of the tactile slabs, which can guide the way in crowded streets for a long time.

Marble has good workability, allowing the surface of tactile slabs to take on richer patterns and textures, blending in with the urban environment.

Limestone is an affordable choice. Its environmentally friendly and non-polluting characteristics also make it an ideal material for green buildings.

Apart from that, materials such as ceramic and concrete are also used in the production of tactile slabs. Each material possesses unique advantages and plays its role in different application scenarios.

The choice of material needs to consider several factors, such as the local climatic conditions, the amount of foot traffic, the budgetary cost, etc. Regardless of the material chosen, it should be ensured that it meets the relevant standards, such as the size, surface texture, and color of the blind tiles, to guarantee the safety, comfort, and effectiveness of the tactile paving slabs.

How to Process the Tactile Paving Slabs?

The selection of materials is the first step in creating quality tactile paving slabs. The selection of hard, wear-resistant, and weather-resistant granite is like breathing life into the tactile paving slabs, giving them a durable quality.

Cutting transforms the boulders into regular-sized slabs, just like tailoring a garment, ready for the laying of tactile paving slabs. State-of-the-art stone cutting equipment ensures the precision of the cut, laying the foundation for subsequent processing.

Surface treatment is the key process of tactile paving slabs. The surface of tactile paving slabs is brushed or sandblasted to increase the friction, just like laying non-slip mats on the guiding path, so that the visually impaired can walk with peace of mind. The surface of the dot-shaped tactile paving slabs is rounded to form raised dots, which act as warning lights on the road to alert them of the road ahead.

Polishing is what gives the tactile paving slabs their glamorous finish. Hand polishing or modern polishing equipment, so that the surface of the stone is smooth and flat, reflecting the glory of the city, but also highlighting the craftsmanship of the fine craftsmanship.

Layers and layers of processes, striving for excellence, create safe, comfortable, beautiful tactile paving slabs, for the visually impaired to build barrier-free city roads, but also to add a warm and caring city.

Which Equipment is used for Tactile Paving Slabs?

The tactile paving slabs processing equipment is mainly designed for the following types of machines and equipment, with different processing options, its efficiency and cost are completely different.

High-precision processing solution

Advantages: tactile paving slabs have high standard, beautiful and smooth surface, strong friction and high safety.

Disadvantages: low production efficiency, high purchase cost of machines.

Note.

The infrared bridge edge cutter developed and manufactured by Dafon is a highly efficient, accurate, easy-to-operate, safe, and reliable stone cutting machine. It utilizes infrared technology to quickly and accurately cut a wide range of stone materials such as granite, marble, rock slabs, tiles, etc. The infrared bridge edge cutting machine has a high precision cutting effect, which can realize fine cutting and ensure the quality and beauty of the products. At the same time, the infrared bridge edge cutting machine adopts an intelligent PLC control system, simple and convenient operation, no need for professional skills, and you can easily complete the stone cutting work!

CNC double-head stone engraving machine is widely used in stone engraving. It can be used to carve marble, granite, sandstone, tactile paving slabs, limestone, travertine, and other materials. It is suitable for making tactile paving slabs, sculptures, bas-reliefs, monuments, tombstones, fireplaces, countertops, sinks and other architectural elements. It can also be used to make signs, plaques, and other decorative items.

Efficient Processing Solution

Advantages: high production efficiency, low cost, convenient on-site processing.

Disadvantages: low degree of automation, relatively low product standards.

Manufacturers of tactile paving slab processing, need to choose the most appropriate processing program according to their situation, taking into account the cost, efficiency, quality, and other factors.

Note:

The grooving (drawing) machine is an extremely effective processing equipment and is widely used in the field of grooving and drawing of blind paths and non-slip floor stone materials. It can accurately process the size that meets the requirements, make the product surface smoother, and improve production efficiency. It also has the advantages of flexible processing specifications and simple operation. The application of this kind of machine has greatly promoted the processing and production of blind roads and anti-slip floors, adding more safety and security to public life.