Intro:

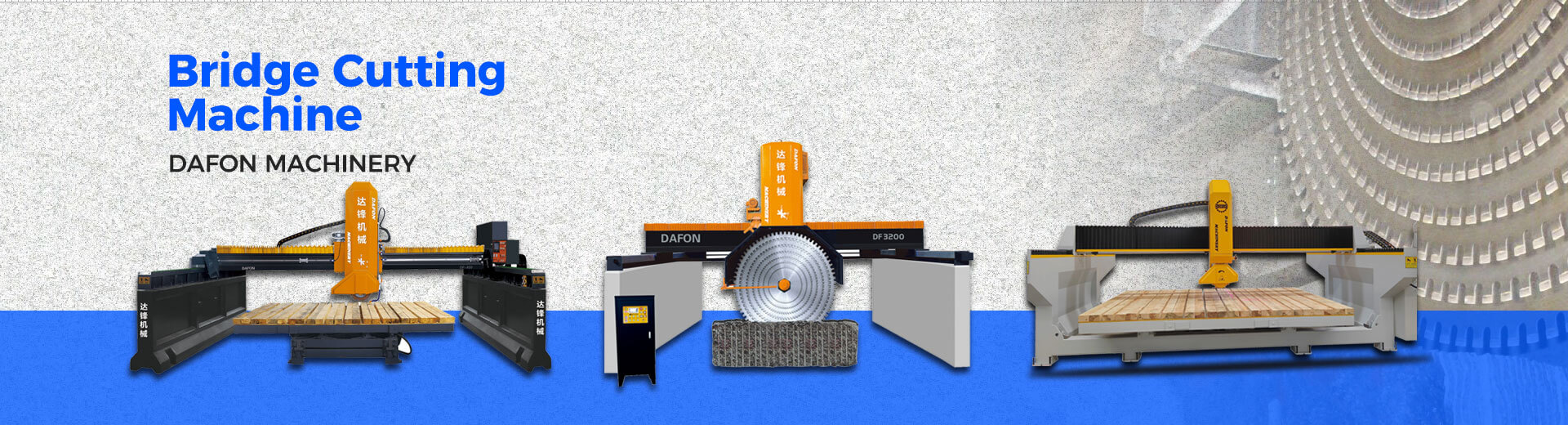

The art of stone shaping and grinding has been around for thousands of years. From ancient Egyptian pyramids to modern-day skyscrapers, stone has always played a vital role in the construction industry. To make it useful as a building material, stones have to be shaped and polished. This is where the grinding stone shaper comes into play. In this article, we'll explore what a grinding stone shaper is, how it works, and its impact on the construction industry.

What Is a Grinding Stone Shaper

A grinding stone shaper is a mechanical device that is used to shape and polish stones. It has a circular grinding wheel that is composed of abrasive particles, such as diamonds or silicon carbide. When the wheel rotates, it grinds away the rough outer layer of the stone, revealing the smooth, polished surface beneath. The stone shaper is typically powered by an electric motor or a hydraulic pump.

The stone shaper comes in different sizes and shapes, depending on the type of stone being worked on. They can be used to shape and polish a wide range of stones, including marble, granite, limestone, sandstone, and quartz. Stone shapers are commonly used in the construction industry to create building facades, countertops, sculptures, and decorative elements.

Working principle of Grinding Stone Shaper

The grinding stone shaper works by rotating the abrasive wheel against the surface of the stone. As the wheel rotates, it grinds away the outer layer of the stone, creating a smooth surface. The degree of the roughness of the surface depends on the size of the abrasive particles and the speed of the wheel rotation. Smaller abrasive particles will create smoother surfaces, while larger particles will create rougher ones.

To achieve the desired shape and finish, thegrinding stone shape operator moves the stone against the rotating wheel. This can be done manually or with the help of a computer numerical control (CNC) machine. The operator can also adjust the speed of the wheel rotation and the pressure applied to the stone to achieve the desired finish.

Product extensions of grinding stone shape

Small stone grinding machines are manual or electric devices that are used to shape and polish small stones,which is extensions of grinding stone shape They are commonly used in the art and jewelry industry to create sculptures, beads, and other decorative objects. Small stone grinding machines come in different sizes and shapes, depending on the type and size of the stone being worked on.

Small stone grinding machines have a circular grinding wheel that is composed of abrasive particles, such as diamonds or silicon carbide. The wheel rotates, grinding away the rough outer layer of the stone, revealing the smooth surface beneath. The operator moves the stone against the wheel to achieve the desired shape and finish.

Small stone grinding machines are typically powered by electricity or batteries. They are portable and can be used in different locations.

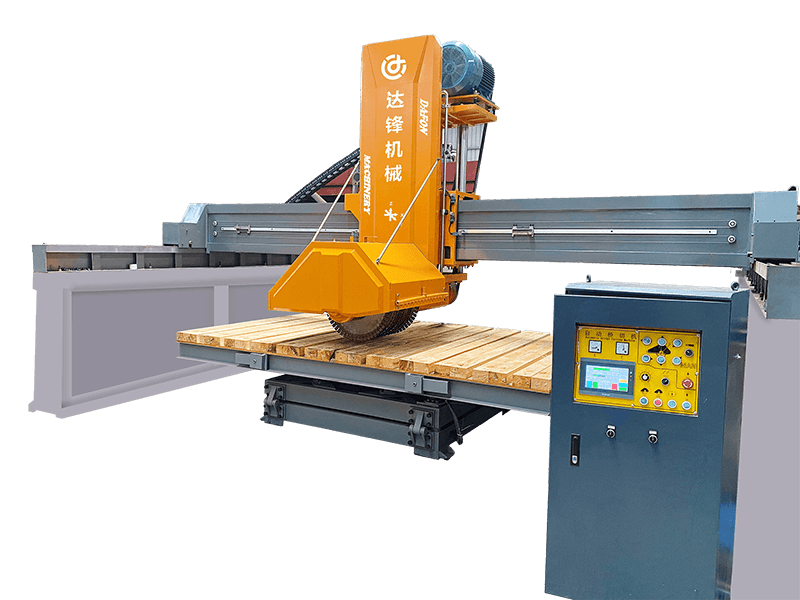

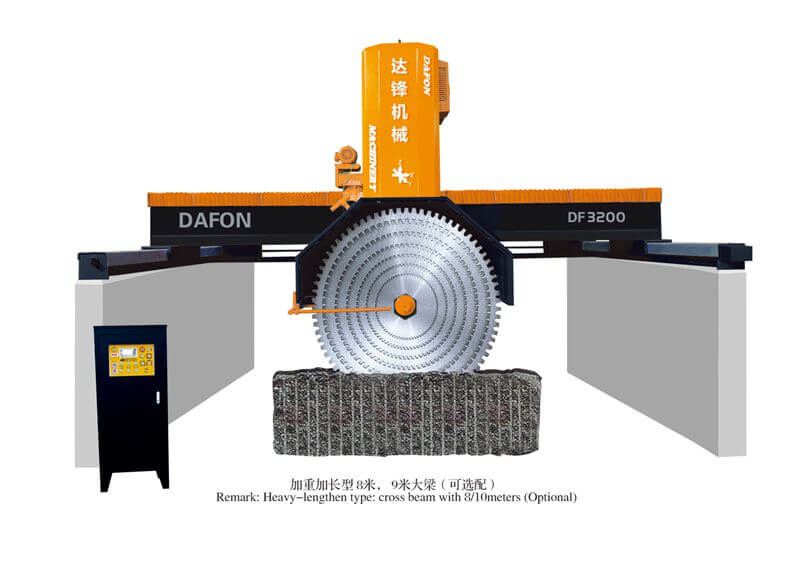

Granite is a popular building material that is commonly used for countertops,which isextensions ofgrinding stone shape too.Flooring, and other decorative applications. To make it suitable for use, granite has to be shaped and polished. This is where the granite grinding machine comes into play.

A granite grinding machine is a mechanical device that is used to shape and polish granite. It has a circular grinding wheel that is composed of abrasive particles, such as diamonds or silicon carbide. The wheel rotates, grinding away the rough outer layer of the granite, revealing the smooth surface beneath. The granite grinding machine is typically powered by an electric motor or a hydraulic pump.

The operator moves the granite against the rotating wheel, adjusting the speed of the wheel rotation and the pressure applied to the granite to achieve the desired finish. Granite grinding machines come in different sizes and shapes, depending on the size and type of granite being worked on.

Conclusion

The grinding stone shaper, small stone grinding machines, and granite grinding machines have changed the way stone shaping and grinding is done. They have made the process faster, more efficient, and more precise. With these machines, craftsmen can now produce complex designs and shapes that were not possible before. The impact of these machines on the construction industry has been significant, leading to improved building materials and speedier construction projects.

Tel: +86-18959843937

Tel: +86-18959843937 Email: danny@dafonmachine.com

Email: danny@dafonmachine.com MP/WhatsApp: +86-18959843937

MP/WhatsApp: +86-18959843937 Manufacturer Address:Hailian Industrial Park, Shuitou Town, Nanan City, Fujian Province, China

Manufacturer Address:Hailian Industrial Park, Shuitou Town, Nanan City, Fujian Province, China